Hitachi, Ltd. And the German Research Centre for Artificial Intelligence Gmbh (DFKI) jointly develop AI for sensor suits

© DFKI

© DFKI

Improving efficiency, ensuring safety, and managing workers’ health through standardization of work skills in production/maintenance sites

In a society in which skilled labor is in shortage and recruiting new workers is becoming increasingly difficult, maintaining the skill level of workers is becoming difficult in manufacturing industry (e.g. car factories) and in maintenance or carrier businesses. As conscious of ensuring the safety and health of workers in production sites has been increasing, assisting workers in preventing danger and maintaining health is considered very important. To keep workers safe and healthy, it is necessary to know the level of physical load during work. In conventional approaches, fixed cameras are used to recognize workers’ activities. However, since cameras are limited in the range they can measure, it has been difficult to quantitatively and stably assess physical load in complex production sites or outside places where it is hard to eliminate blind spots.

In order to address this problem, DFKI and Hitachi developed new AI based technology that uses the motion data of a worker, measured directly with wearable devices, to recognize and evaluate physical load on the worker’s body. This AI based technology was advanced from the AI based technology developed in 2017*2, which recognizes worker’s activities (e.g. tightening a screw) using quantitative data collected through arm-band sensors and eye tracking glasses in order to prevent human errors. Combination of Hitachi’s human activity recognition technology for industry and DFKI’s Deep Learning technology enabled the development of this AI technology. Features of the new AI driven technology are as follows:

Technology to directly measure body movements in various human actions and quantify physical load

Sensors in wearable devices directly measure the movements of over 30 body parts necessary to recognize basic human actions. The collected data is analyzed by AI driven models which learned how to estimate the position of each body part in advance. AI powered technology recognizes the data of certain action from the combination of each body part’s position, which allows the quantification of physical load from the action using time-series data processing technology based on Deep Learning.

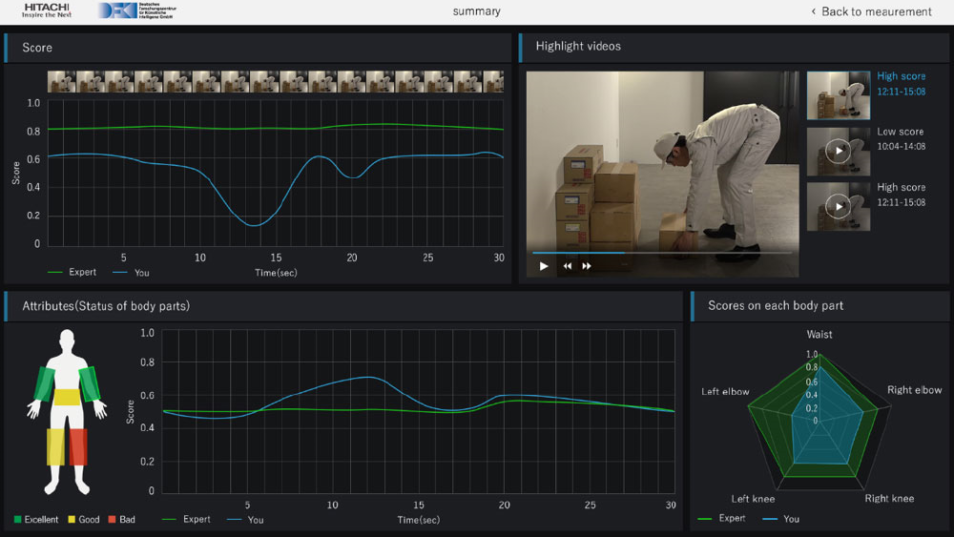

Technology to estimate physical load in real time and present differences from proper working posture to workers

By automatically comparing the motion data of the model worker measured in advance and that of a worker for each body part, AI driven model identifies specific movements and body parts that account for significant differences between them. As a result, it indicates to the worker its assessment of body parts that are causing higher physical load in an easy manner.

As an experiment, this AI based technology was applied to action to pick up heavy object. The results of the experiment confirmed that it can perform real-time estimation of quantitative values for the physical load of the action. In addition, for actions which contain bad movement, it was confirmed feedback on each body part could be provided, like movements of waist and knees are different from the model worker. Hitachi and DFKI plan to examine the effectiveness of giving instruction for safer operations in production sites with this technology.

Hitachi and DFKI will utilize the newly developed AI driven technology for operation assistance and prevention of dangerous actions in order to contribute to ensuring workers’ safety, managing workers’ health, and improving worker education in various production sites. Also, even though this AI technology was originally developed for workers in manufacturing industry and in maintenance or carrier businesses as a technology to measure and evaluate the movement of a human body, it is also expected to be applied in other industries such as sports or entertainment in the future. Moreover, drawing on previously developed human activity recognition AI, Hitachi and DFKI will aim to realize more efficient and safer working environment by contributing to the improvement of productivity.

Hitachi has been operating a transfer lab at DFKI in Kaiserslautern since April 2016 with the aim of jointly developing a cutting-edge AI technology of human-activity-recognition for industry.

Hitachi and DFKI will exhibit part of this technology at Hannover Messe 2019, hall 2, booth C59, to be held from 1-5 April 2019 in Hannover, Germany.

Copyright: DFKI

Contact:

Prof. Dr. Prof. h.c. Andreas Dengel

Research Department Smart Data & Knowledge Services

Phone: +49 631 20575 1000

Andeas.Dengel@dfki.de

Dr. Sheraz Ahmed

Research Department Smart Data & Knowledge Services

Phone: +49 631 20575 4818

Sheraz.Ahmed@dfki.de

Hitachi, Ltd. Research & Development Group

Contact form: https://www8.hitachi.co.jp/inquiry/hqrd/news/en/form.jsp

Press contact:

Christian Heyer

DFKI Corporate Communications Kaiserslautern

German Research Center for Artificial Intelligence GmbH (DFKI)

Trippstadter Straße 122

67663 Kaiserslautern

Germany

uk-kl@dfki.de

Hitachi, Ltd. Corporate Brand & Communication Division, PR・IR Dept.

[Representative: Matsumura, Izumisawa]

6-6, Marunouchi 1-chome, Chiyoda-ku, Tokyo, 100-8280 Japan

Phone: +81-3-5208-9324

Register for our Newsletter!

The DWIH Tokyo Newsletter provides timely information on German-Japanese funding programs, event invitations and news from research and innovation. Sign up now!