German-Japanese battery research - new projects launched

Germany and Japan have been successfully researching secondary battery systems for many years. Four new German-Japanese research projects were launched on 01.01.2022. The pre-competitive research pro-jects address the development of new materials as well as novel and advanced analytical methods to study structures and elucidate processes in battery cells in the field of post-lithium-ion technologies with a focus on solid-state batteries. The projects combine complementary expertise in Germany and Japan and contribute to a better qualitative and quantitative understanding of the addressed issues through a continuous ex-change of young researchers.

The projects are funded by the German Federal Ministry of Education and Research (BMBF) and the Japa-nese New Energy and Industrial Technology Development Organization (NEDO).

Specifically, the projects are as follows:

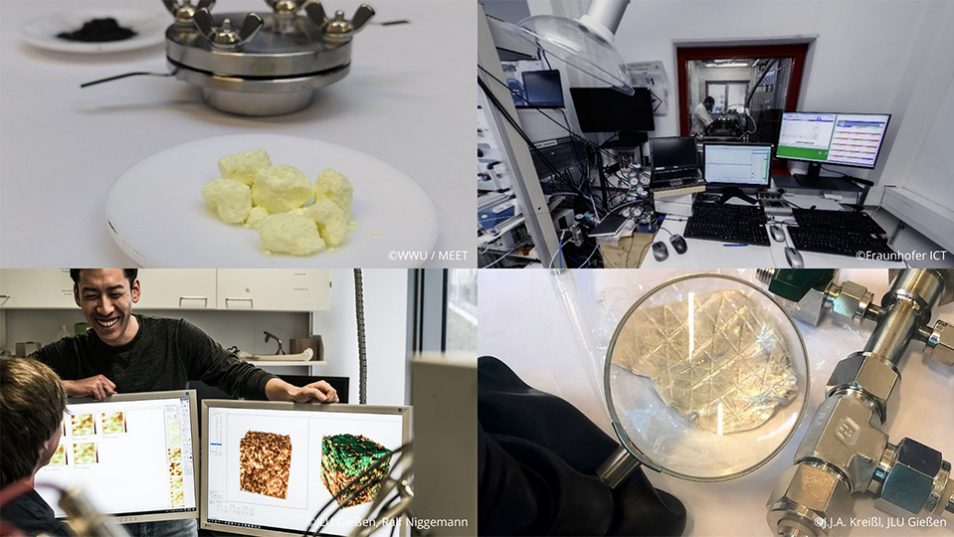

AReLiS-2: Analysis of cathode and electrolyte reactions in lithium-sulfur and lithium-metal sulfide batteries- solid state electrolytes.

Sulfur as a cathode material offers high capacity, low raw material cost, low environmental footprint, and globally distributed raw material reserves. Practical application is hindered by the rapid aging of battery cells to date. Various approaches, such as the use of tailored electrolytes and electrodes or the use of polymer and solid-state electrolytes, are intended to improve the lifetime of lithium-sulfur batteries. The basic principles of these approaches were investigated in the previous German-Japanese project “AReLiS”, which focused on the reactions of cathodes with liquid electrolytes. For the development of long-term stable lithium-sulfur batteries, great potential lies in the use of pure polymer, solid and hybrid electrolytes. This is where “AReLiS-2” comes in: The project focuses on characterizing fundamental mechanisms of batteries operated with sulfur-containing cathodes as well as polymer, solid-state and hybrid electrolytes. The consortium brings together extensive expe-rience in materials science, cell manufacturing, and instrumental chemical analysis. Insights into these critical processes are expected to pave the way for the application of next-generation battery systems.

Partners: Prof. Osaka, Waseda Univ. / Prof. Winter, WWU Muenster

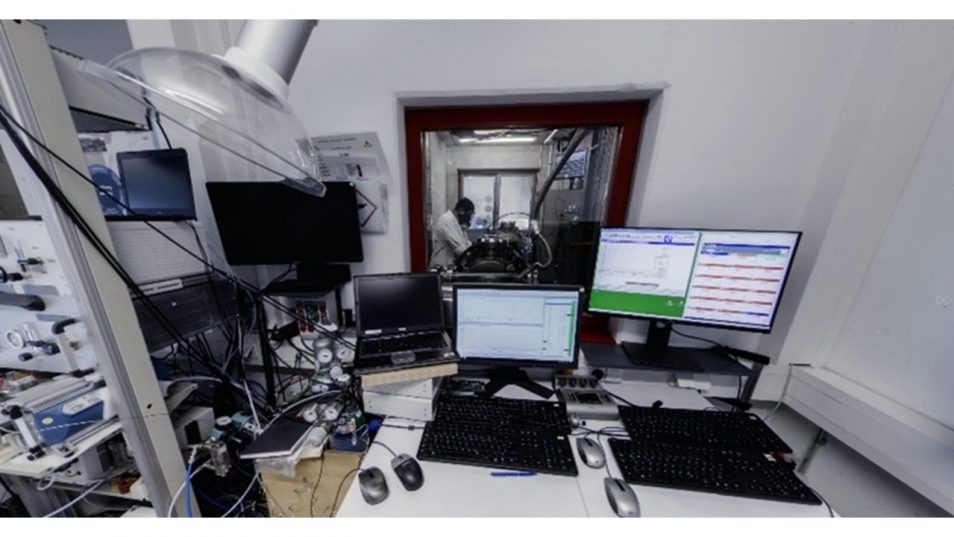

SolidSafe: Solid State Battery Safety Testing

Mechanical damage or heat exposure can cause batteries to catch fire or explode. Lithium-ion bat-teries with solid-state electrolytes promise a lower safety risk than lithium-ion batteries with liquid electrolytes, but the full extent of the remaining safety risk and the underlying mechanisms inside the battery are not yet fully understood. To this end, in the German-Japanese project “SolidSafe”, corre-sponding solid-state battery cells will be fabricated from different starting materials, characterized, and subjected to extensive safety testing under a wide variation of operating conditions. The exper-imental data will be stored in a central database. 3D simulations will also be used to shed more light on the underlying processes inside the solid-state battery in the event of damage, overcharging and overheating, so that the number of time-consuming safety tests can be reduced.

Partners: Prof. Abe, Kyoto Univ. / Prof. Tuebke, Fraunhofer ICT

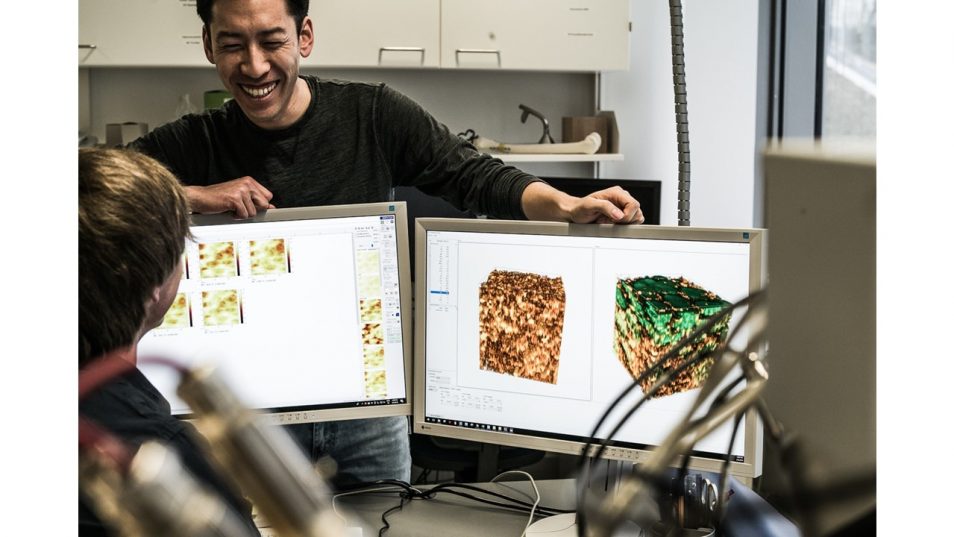

InCa²: Interfaces in All-Solid-State Composite Cathodes – Improving Performance and Under-standing Protective Layers

While the material and process technologies for the production of lithium-ion batteries with liquid electrolytes are well developed, considerable research activities are still required for the successful establishment of solid-state batteries. Due to their high conductivity, so-called sulfidic solid electro-lytes are promising candidates for use in high-performance electrode materials, more precisely cath-ode composites. However, their stability has been insufficient up to now. In the German-Japanese project “InCa²”, functional coatings for the cathode materials are therefore to be developed to in-crease their stability and systematically investigated by means of tailored analysis. The thickness of the cathode layer used and the so-called filling level of cathode material in the composite and its influence on the capacity and performance of the battery cell will also be analyzed in detail. In this way, a detailed and quantitative understanding of the interactions and aging effects within the cath-ode composites will be established in order to increase the performance and longevity of solid-state batteries. Overall, the “InCa²” project is thus contributing to the knowledge-based further develop-ment of solid-state batteries with their great potential for electromobility.

Partners: Prof. Kanno, Tokyo Institute of Technology / Prof. Janek, JLU Giessen

OsabanPlus: Operando surface analysis for batteries with 3D-structured anodes with high performance and longer service life

The components of commercial lithium-ion batteries have been steadily improved over the past dec-ades. Over time, the progress of this development has become smaller. This indicates that the max-imum performance of the currently used materials will soon be reached. In order to further increase the performance and lifetime of future batteries, the use of new types of electrodes will become in-dispensable. For the successful commercial use of these novel materials in batteries, however, re-search and development efforts are still required, especially with regard to stability and durability. The background to this is, among other things, the secondary reactions of the electrolyte at the elec-trode. A better understanding of the processes at the electrode-electrolyte interface is therefore cru-cial for the further development of electrodes.

Such processes are being investigated in the German-Japanese project “OsabanPlus” in order to gain further knowledge about next-generation electrodes. The focus is increasingly on so-called 3D-structured conversion electrodes. These are being investigated by means of operando analysis. The knowledge gained from the project can then be used to generate approaches for making the materi-als used more efficient and more durable.

Partners: Prof. Abe, Kyoto Univ. / Prof. Schröder, TU Braunschweig

If you have any questions, please contact Dr. Lothar Mennicken, Head of the Science and Technology Section, German Embassy Tokyo.

EmailThe DWIH Tokyo newsletter provides timely information about open calls and events from research and innovation in Germany and Japan: Click here to register for the newsletter in English

Updated on: May 17, 2022